Broken lug nuts can be a frustrating and potentially dangerous issue for vehicle owners. In most cases, a broken lug nut can be fixed by replacing both the damaged lug nut and the wheel stud it’s attached to, but this can be a complicated (and time consuming) repair. There’s no avoiding it, however, as this repair is crucial for maintaining proper wheel attachment and overall vehicle safety. Not fixing it can potentially lead to wheel detachment and accidents.

While some issues can be addressed with DIY methods like using a lug nut extractor socket, others require professional intervention, such as welding or replacing a wheel stud. Remember that prevention is always the best approach, so use the correct tools, avoid over-tightening, and regularly inspect your lug nuts to ensure they are in good condition.

Fixing a broken lug nut involves more than simply replacing the nut itself. The wheel stud, which is the threaded bolt that the lug nut screws onto, often needs replacement too. This is because the stud can become damaged when a lug nut breaks or when attempts are made to remove a stubborn nut.

The process of replacing a broken lug nut and wheel stud typically involves removing the wheel and brake components to access the back of the wheel hub. From there, the damaged stud can be pushed out and a new one installed. While this task can be done at home with the right tools and knowledge, many people choose to have it done by a professional to ensure proper installation and safety.

Dealing with a Damaged Wheel Lug Nut: What to Do

Assessing the Damage

Before you can fix a broken wheel lug nut, you need to determine the extent of the damage. Is the lug nut rounded off, stripped, or completely broken? This will influence your approach to fixing it.

Rounded-off Lug Nut

If the lug nut is rounded off, it means the corners have been worn down, making it difficult to grip with a wrench. This often happens due to over-tightening or using the wrong size wrench.

Stripped Lug Nut

A stripped lug nut has damaged threads, either on the nut itself or on the wheel stud. This can happen if the lug nut is cross-threaded or forced onto the stud.

Broken Lug Nut

In some cases, the lug nut may be completely broken or sheared off. This is usually caused by excessive force or rust and corrosion.

Possible Solutions

Depending on the type of damage, you may be able to fix the lug nut yourself or you may need professional assistance. Here are some common solutions:

Using a Lug Nut Extractor Socket

For rounded-off lug nuts, a lug nut extractor socket can be a lifesaver. These sockets have a reverse spiral design that grips the rounded nut tightly, allowing you to remove it.

Welding a New Nut On

If the lug nut is stripped or broken, a mechanic can weld a new nut onto the damaged one. This provides a fresh surface to grip with a wrench.

Replacing the Wheel Stud

If the wheel stud is damaged, it will need to be replaced. This is a more involved repair that typically requires removing the wheel hub.

Prevention is Key

You can often avoid lug nut problems by taking some preventive measures:

- Use the correct size wrench.

- Don’t overtighten the lug nuts.

- Apply anti-seize lubricant to the wheel studs to prevent rust and corrosion.

- Have your lug nuts checked and retorqued periodically by a mechanic.

When to Seek Professional Help

| Situation | Recommendation |

|---|---|

| You’re not comfortable working on your car. | Seek professional help. |

| The lug nut is severely damaged. | Seek professional help. |

| You’ve tried the solutions above and they haven’t worked. | Seek professional help. |

Key Takeaways

- Broken lug nuts often require replacing both the nut and wheel stud

- Proper repair is essential for wheel security and vehicle safety

- Professional help may be advisable for those unsure about the repair process

Assessing Lug Nut and Wheel Stud Damage

Proper inspection of lug nuts and wheel studs is key for vehicle safety. Spotting problems early can prevent accidents and costly repairs.

Identifying a Broken Lug Nut

Broken lug nuts can be spotted by looking for cracks or missing pieces. Check each nut carefully. A broken nut may not hold the wheel tight enough.

Signs of damage include:

• Visible cracks or chips

• Rust or corrosion

• Rounded edges

• Loose fit on the stud

Stripped threads are another common issue. If a nut spins freely without tightening, it likely needs replacement.

Always wear eye protection when checking lug nuts. Small metal pieces can fly off during inspection.

Evaluating Wheel Stud Condition

Wheel studs should be straight and have clean threads. Damaged wheel studs can cause wheel wobble or detachment.

To check stud health:

- Remove the wheel

- Look for bent or broken studs

- Check for rust or wear on threads

- Try to wiggle each stud (they should not move)

A stud that’s too short or has damaged threads needs replacement. Bent studs can’t be fixed and must be swapped out.

If unsure about stud condition, ask a mechanic to check. They can spot less obvious damage that might be missed.

Procedure for Lug Nut and Wheel Stud Replacement

Replacing a broken lug nut or wheel stud is a straightforward process. It requires some basic tools and careful attention to detail. Following the correct steps ensures a safe and secure wheel attachment.

Removing the Damaged Components

First, loosen the lug nuts slightly while the wheel is still on the ground. Jack up the vehicle and secure it with jack stands. Remove the lug nuts and take off the wheel.

For drum brakes, remove the brake drum. With disc brakes, the caliper may need to come off. Locate the damaged stud on the wheel hub.

Use a hammer to tap out the old stud from behind the hub. If it’s stubborn, a sledgehammer might be needed. Be careful not to damage other parts.

Clean the stud hole with a wire brush. Check for any damage to the hub that might need fixing.

Installing New Wheel Stud

Get a new stud that matches the old one exactly. Auto parts stores can help find the right fit.

Put the new stud through the hole from behind the hub. Use washers to help pull it into place.

Thread on a lug nut backwards. As you tighten it, it will pull the new stud into position.

Keep tightening until the stud is fully seated. The head should be flush with the back of the hub.

Remove the lug nut and washers. Check that the stud is secure and doesn’t move.

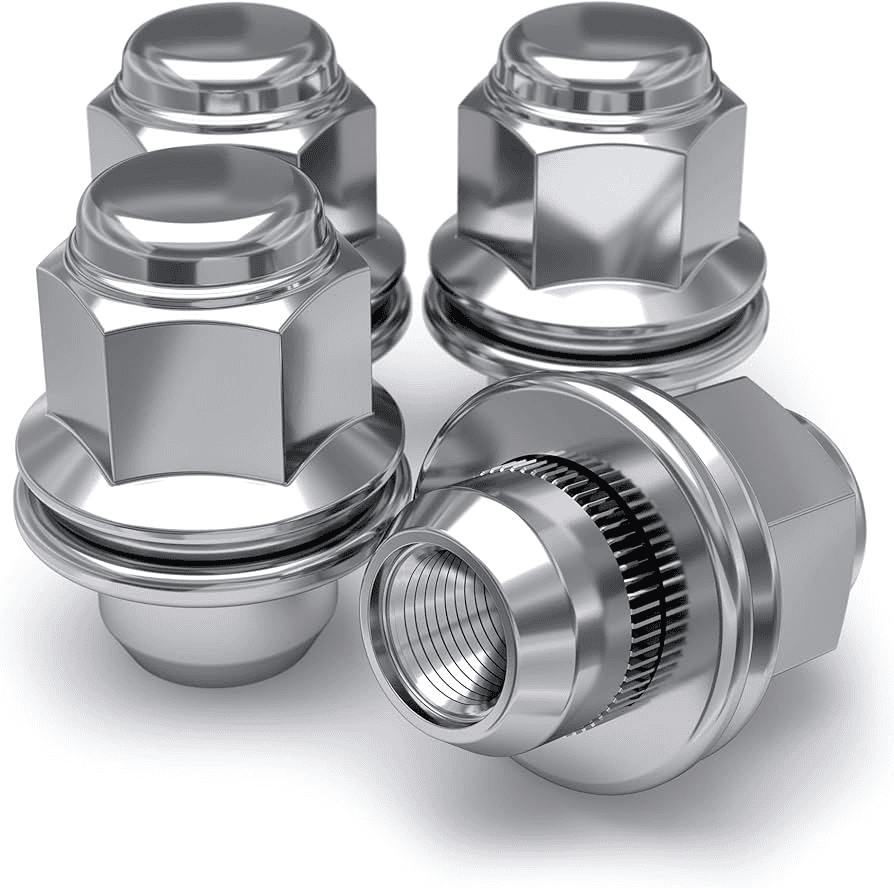

Securing the Wheel with New Lug Nut

Put the wheel back on. Thread on new lug nuts by hand at first.

Use a lug wrench to tighten them in a star pattern. Don’t fully tighten yet.

Lower the vehicle so the wheel touches the ground. This prevents the wheel from spinning.

Use a torque wrench to tighten the lug nuts to the correct spec. Find this in the owner’s manual.

Tighten in a star pattern. Go around at least twice to ensure even pressure.

Double-check all lug nuts are tight. Take a short test drive and re-check the tightness.

Frequently Asked Questions

Lug nut issues can be serious. Knowing how to handle broken lug nuts and studs is key for driver safety. Here are answers to common questions about this topic.

How is a broken lug nut stud replaced?

A mechanic removes the wheel and brake parts to access the hub. They punch out the broken stud from behind. A new stud is inserted and secured with a lug nut. The process requires special tools and skills.

What tools are required for removing a broken lug nut?

Basic tools include a lug wrench, socket set, and pliers. For stubborn lug nuts, you may need a breaker bar or impact wrench. Special sockets can grip damaged lug nuts.

What is the estimated repair cost for a broken lug nut stud?

Repair costs vary based on the vehicle and labor rates. The part itself is cheap, often under $5. Labor can range from $50 to $150 per stud. Some shops charge a flat fee for replacing multiple studs.

Is it safe to operate a vehicle with a missing lug nut?

Driving with a missing lug nut is risky. It puts extra stress on the other lug nuts. This can lead to wheel wobble or detachment. Experts advise replacing missing lug nuts right away.

What should be done immediately when a lug nut breaks?

Stop driving as soon as it’s safe. Check the other lug nuts for tightness. If possible, replace the broken lug nut with a spare. If not, drive slowly to the nearest repair shop or call for a tow.

Can driving with a broken lug bolt cause further vehicle damage?

Yes, it can cause major problems. A loose wheel can damage the brake rotor, wheel bearings, and suspension parts. In extreme cases, the wheel could come off while driving. This poses a serious safety risk.