A washing machine coupler is a small but crucial component that connects the motor to the transmission in direct-drive washing machines. This part allows the motor to spin the washer tub during wash and spin cycles. A broken motor coupler is a common cause of washing machines that won’t agitate or spin, even when the motor is running.

Recognizing the signs of a faulty coupler can save time and money on repairs. If your washer fills with water but doesn’t agitate, or if it drains but doesn’t spin, the coupler may be the culprit. These symptoms often indicate that the coupler has worn out or broken, preventing power transfer from the motor to the transmission.

Replacing a washing machine coupler is a manageable DIY repair for many homeowners. The process typically involves accessing the motor, removing the old coupler, and installing a new one. This repair can restore function to a non-working washer and is often more cost-effective than calling a professional or replacing the entire appliance.

Understanding the Washing Machine Coupler

The washing machine coupler is a small but crucial component in many top-load washers. It plays a vital role in the machine’s operation. Think of it as the link between the motor, which provides the power, and the transmission, which spins the wash basket.

How It Works

- Connection: The coupler connects the drive motor to the transmission. It’s usually located between them, at the bottom of the washing machine.

- Flexibility: The coupler is made of a flexible material, often rubber or plastic. This allows it to absorb shocks and vibrations during the wash cycle.

- Protection: The coupler acts as a safety device. If the washing machine becomes overloaded or jammed, the coupler will break. This protects the motor and transmission from more expensive damage.

Signs of a Broken Coupler

- Noisy Operation: If you hear a loud banging or clunking sound during the wash cycle, it could indicate a broken coupler.

- Washing Machine Won’t Spin: If the washer fills with water but doesn’t spin, the coupler might be the culprit.

- Motor Runs, but the Basket Doesn’t: If the motor is running but the wash basket isn’t moving, the coupler may have failed.

Replacing a Coupler

Replacing a washing machine coupler is a relatively simple repair that many people can do themselves. You can find replacement couplers at most appliance parts stores.

Here are the basic steps:

- Unplug the washing machine.

- Remove the cabinet. This usually involves removing a few screws.

- Locate the coupler. It’s usually a small, white plastic piece connecting the motor and transmission.

- Remove the old coupler. This may involve removing a few screws or clips.

- Install the new coupler. Make sure it’s properly aligned.

- Reassemble the washing machine.

- Plug the washing machine back in and test it.

You can find many helpful videos and articles online that provide more detailed instructions for replacing a washing machine coupler.

Maintaining Your Washing Machine

Regular maintenance can help prevent coupler problems and extend the life of your washing machine. Here are a few tips:

- Balance your laundry loads. Don’t overload the washer.

- Avoid washing heavy items like rugs or blankets. These can put extra stress on the coupler.

- Clean the washer regularly. This helps prevent clogs and build-up that can damage the coupler.

- Inspect the coupler periodically. If you see any signs of wear and tear, replace it before it breaks.

By understanding the function of the washing machine coupler and following these maintenance tips, you can help keep your washing machine running smoothly for years to come.

Key Takeaways

- A broken motor coupler can cause washing machines to stop agitating or spinning

- Signs of a faulty coupler include a running motor with no drum movement

- Replacing the coupler is often a cost-effective DIY repair for non-working washers

Fundamentals of Washing Machine Couplers

Washing machine couplers play a crucial role in connecting the motor to the transmission. These small but essential components ensure the proper transfer of power for effective washing cycles.

Understanding Coupler Functionality

The motor coupler acts as a link between the drive motor and the transmission in top-loading washing machines. It transfers rotational power from the motor to the transmission, which then moves the agitator or drum. Couplers are designed to break if the washer becomes overloaded, protecting more expensive components from damage.

When a coupler fails, the washer may fill with water but not agitate or spin. This occurs because the motor runs but cannot transfer power to the transmission. Coupler failure is often mistaken for motor problems, leading to unnecessary repairs or replacements.

Common Types of Couplers

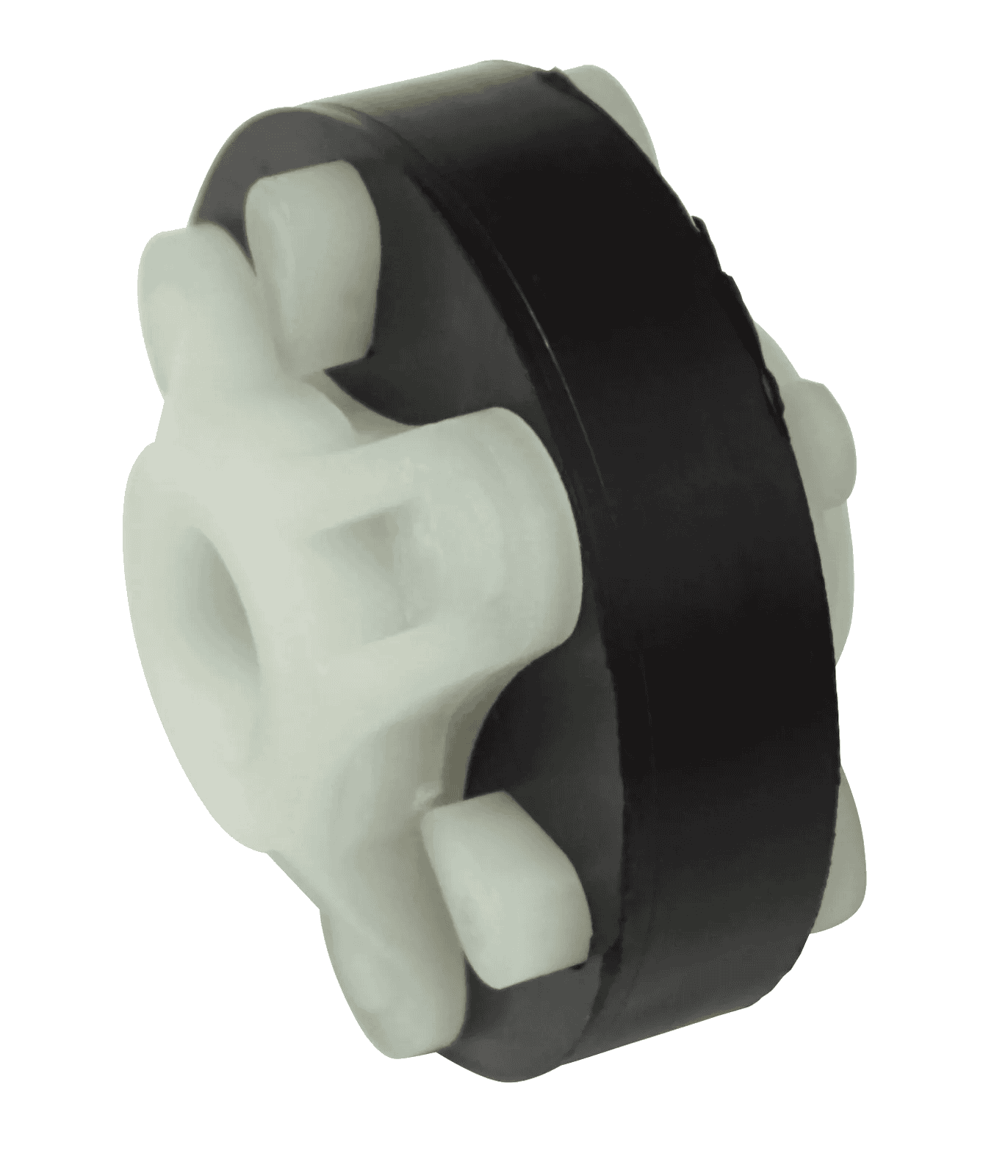

Direct drive couplers are the most common type used in top-loading washers. They consist of two plastic drive forks connected by a rubber shock absorber. The plastic parts fit onto the motor shaft and transmission input shaft, while the rubber component absorbs vibrations and minor misalignments.

Some newer models use metal couplers for increased durability. These couplers are less likely to break but may transfer more stress to other components. Rubber couplers offer a balance between durability and protection for other parts.

Identifying the correct coupler type is crucial for proper replacement. Washers from different brands and models may use specific coupler designs. Always consult the washer’s manual or a parts diagram to ensure the right fit.

Brand-Specific Coupler Information

Washing machine couplers vary across different brands and models. Each manufacturer designs couplers with unique features to fit their specific machines.

Whirlpool Coupler Characteristics

Whirlpool couplers are known for their durability and reliability. These couplers typically consist of three parts: two plastic drive forks and a rubber shock absorber in the middle. The plastic components connect to the motor shaft and transmission, while the rubber piece reduces vibration.

Whirlpool couplers often have a distinctive star-shaped pattern on the drive forks. This design helps ensure a secure fit and efficient power transfer. Many Whirlpool models use a standardized coupler size, making replacements easier to find.

Some newer Whirlpool washers feature enhanced coupler designs with reinforced materials for extended longevity. These improved couplers aim to reduce the frequency of replacements and increase overall machine performance.

Kenmore and Maytag Coupler Features

Kenmore and Maytag washers often share similar coupler designs due to their manufacturing relationships. These couplers typically feature a three-piece construction like Whirlpool models. The main difference lies in the specific dimensions and connection points.

Kenmore couplers may have slight variations depending on the exact model and year of manufacture. Some older Kenmore washers use metal couplers, which are more durable but can be noisier than plastic versions.

Maytag couplers are known for their robust construction. Many Maytag models utilize couplers with thicker plastic components and larger rubber cushions. This design helps withstand higher torque loads and extends the coupler’s lifespan.

Roper, Crosley, and Estate Model Considerations

Roper, Crosley, and Estate washing machines often use couplers similar to those found in Whirlpool models. These brands are part of the Whirlpool Corporation family, leading to shared components across product lines.

Roper washers typically feature basic coupler designs optimized for cost-effectiveness. These couplers may have simpler shapes but still maintain adequate performance for most household needs.

Crosley and Estate models often incorporate mid-range coupler designs. These couplers strike a balance between durability and affordability. Some Crosley and Estate washers use reinforced plastic in their couplers to enhance longevity.

When replacing couplers in these brands, it’s important to verify compatibility. While many parts are interchangeable, slight variations can exist between specific models and production years.

Step-by-Step Repair Guide

Replacing a washing machine coupler requires careful diagnosis and precise execution. This guide outlines the key steps to identify and fix coupler issues effectively.

Diagnosing Coupler Issues

A broken motor coupler often manifests as a non-spinning washer drum. To confirm this issue, start a wash cycle and listen for the motor running without agitation or spin. Check if the washer fills with water but fails to agitate. Set the dial to spin cycle; if the motor runs but the drum doesn’t spin, a broken coupler is likely.

Inspect the coupler visually by tilting the washer back 45 degrees. Look for cracked or worn rubber pieces on the coupler. A damaged coupler will show clear signs of wear or breakage.

Tools Needed for Coupler Replacement

Gather these essential tools before starting the repair:

- Putty knife

- Flathead screwdriver

- Phillips head screwdriver

- Pliers

- Socket set

- Work gloves

- Flashlight

Ensure you have a replacement coupler that matches your washer model. Consult the washer’s manual or contact the manufacturer for the correct part number.

Replacement Procedure

Start by unplugging the washer and turning off the water supply. Remove the control panel by unscrewing the retaining screws. Disconnect the lid switch wiring harness.

Tilt the washer cabinet back and prop it securely. Locate the drain pump and disconnect it from the drive motor shaft. Move it aside carefully.

Remove the old coupler using pliers or a flathead screwdriver. Clean the shaft and surrounding area. Install the new coupler, ensuring proper alignment with both the motor and transmission shafts.

Reassemble the washer in reverse order. Reconnect the drain pump and lid switch. Secure the cabinet and control panel. Test the washer to confirm proper operation.

Maintenance and Troubleshooting

Regular maintenance and prompt troubleshooting can extend the life of a washing machine coupler. Proper care helps prevent issues and enables early detection of potential problems.

Preventive Maintenance Tips

Keep the washing machine level to reduce stress on the coupler. Check and adjust the leveling feet every few months. Clean the washer’s drum and tub regularly to prevent debris buildup that could strain the coupler. Avoid overloading the machine, as this can put excessive pressure on the coupler. Use the appropriate amount of detergent to prevent soap residue accumulation. Run an empty hot water cycle with vinegar monthly to clean internal components. Inspect hoses for leaks or cracks and replace them if necessary. These simple steps can significantly reduce the risk of coupler failure.

Identifying Common Symptoms of Coupler Failure

A broken coupler often manifests as a non-spinning drum during the spin cycle. The washer may fill with water and drain properly, but the agitator won’t move. Unusual noises, such as grinding or clicking sounds, can indicate a failing coupler. If the motor runs but the drum doesn’t spin, it’s likely a coupler issue. Check for water leaks around the base of the machine, as a damaged coupler can cause misalignment. Intermittent spinning or slow spin speeds may also point to coupler problems. If these symptoms occur, prompt inspection and replacement of the coupler may be necessary to prevent further damage.

Frequently Asked Questions

Motor couplers play a crucial role in washing machine function. Understanding common issues, replacement costs, and procedures can help diagnose and fix problems efficiently.

How can you tell if a washer motor coupler is defective?

A defective motor coupler often causes the washer to stop spinning or agitating. Listen for the motor running without the drum moving. Check for unusual noises during operation. A visual inspection may reveal cracks, wear, or broken pieces on the coupler.

What are the common causes of a washing machine coupler failure?

Overloading the washer is a primary cause of coupler failure. Constant stress from heavy loads can wear out the coupler prematurely. Age and regular use also contribute to natural wear and tear. Manufacturing defects, though rare, can lead to early failure in some cases.

What is the estimated cost for replacing a washing machine coupler?

The cost of a motor coupler ranges from $5 to $30 for the part alone. Professional installation typically adds $100 to $200 to the total cost. DIY replacement can save on labor costs but requires some technical skill and the right tools.

What steps are involved in replacing a motor coupler in a Whirlpool washing machine?

Start by unplugging the washer and removing the cabinet. Disconnect the pump from the motor shaft. Remove the motor mounting bolts and slide out the motor. Replace the old coupler on both the motor shaft and transmission input shaft with the new one.

How do you determine the right coupler replacement for a Kenmore washing machine?

Check the washer’s model number, usually found inside the door or on the back panel. Use this number to search for compatible parts online or consult a parts diagram. Many Kenmore washers use Whirlpool parts, so cross-referencing can be helpful.

Are there specific tools required for changing a washer’s motor coupler?

Basic tools needed include a socket set, screwdrivers, and pliers. A putty knife helps separate the washer cabinet. Some models may require specialty tools like a spanner wrench. Having a digital camera or smartphone to document the disassembly process can be useful.