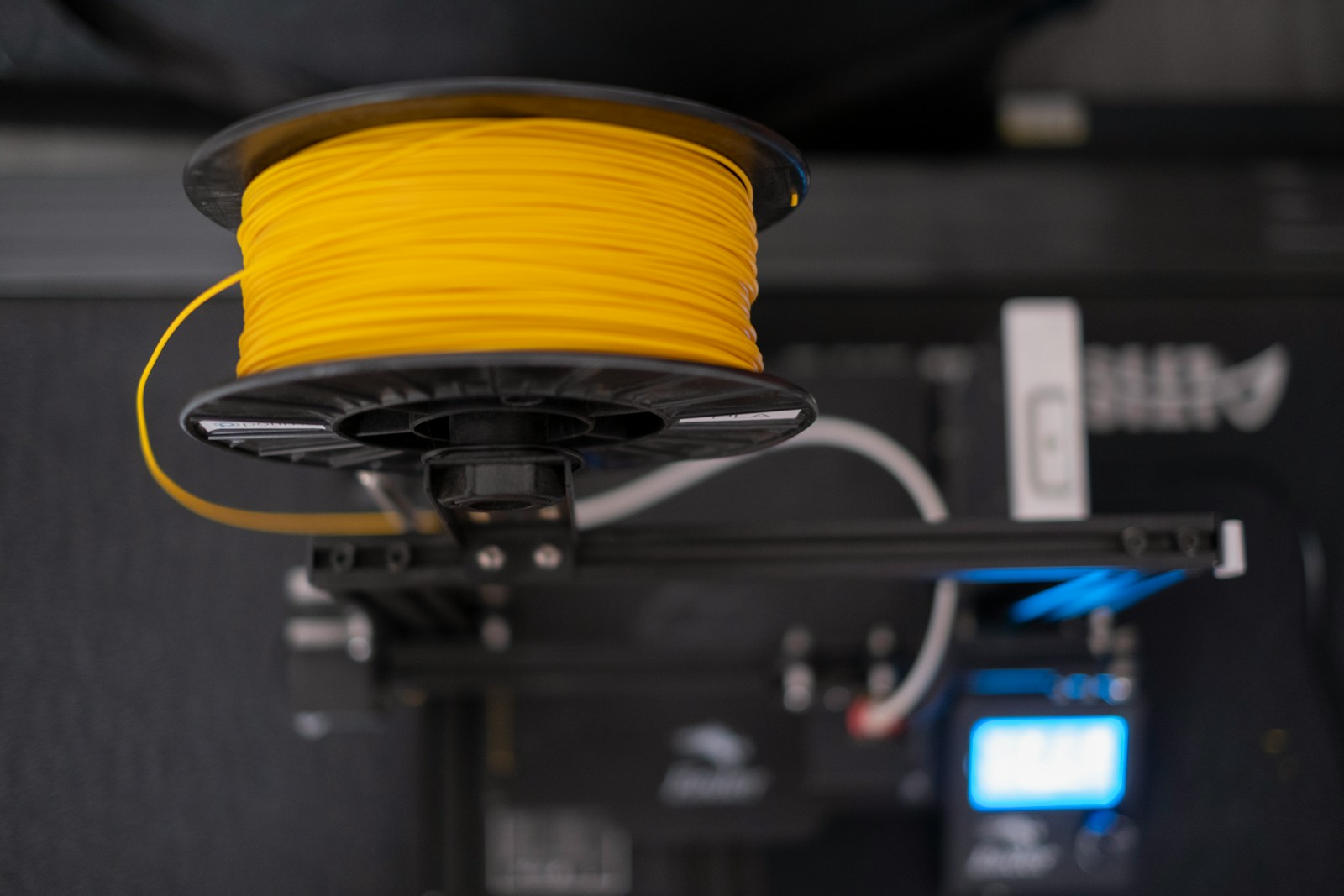

Looking to get started with 3D printing? Understanding what goes into your printer’s filament is key to success. 3D printer filament is the material that feeds through your machine to create objects layer by layer. Most 3D printer filaments are made of thermoplastics, which are polymers that melt rather than burn when heated, allowing them to be shaped and molded into various forms.

The most common filament material is PLA (polylactic acid), which is unique because it’s made from organic materials rather than petroleum-based substances like most other options. Filament comes as one continuous slender plastic thread spooled into a reel for storage and easy feeding into your printer. Different materials offer various properties – some are stronger, others more flexible, and some can withstand higher temperatures.

What Is 3D Printer Filament Made Of?

3D printer filament is the raw material used in FDM (Fused Deposition Modeling) 3D printers. It’s a thermoplastic—a type of plastic that melts when heated and hardens when cooled—extruded into thin strands and wound onto spools.

But not all filaments are the same. Each type is made from different base materials, giving it unique strength, flexibility, heat resistance, and print behavior.

This guide explains what 3D printer filament is made of, the most common materials, and how they’re used.

What Is 3D Printer Filament?

3D printer filament is:

- A continuous plastic strand (usually 1.75 mm or 2.85 mm in diameter)

- Fed into a heated nozzle

- Melted and deposited layer by layer to create an object

Most filaments are made from polymers, often blended with additives to improve performance or appearance.

Common 3D Printer Filament Materials

1. PLA (Polylactic Acid)

Made from:

- Renewable resources like corn starch, sugarcane, or cassava

Key properties:

- Biodegradable under industrial conditions

- Low melting temperature

- Minimal warping

- Slightly brittle

Best for:

- Beginners

- Prototypes

- Decorative items

- Educational use

✅ Easy to print

❌ Not heat‑resistant

2. ABS (Acrylonitrile Butadiene Styrene)

Made from:

- Petroleum‑based plastic (same material used in LEGO bricks)

Key properties:

- Strong and impact‑resistant

- Higher melting point than PLA

- Can warp without an enclosed printer

Best for:

- Functional parts

- Automotive components

- Housings and enclosures

✅ Durable

❌ Produces fumes when printing

3. PETG (Polyethylene Terephthalate Glycol)

Made from:

- Modified PET plastic (similar to plastic bottles)

Key properties:

- Strong and flexible

- Moisture‑resistant

- Good layer adhesion

Best for:

- Outdoor parts

- Food‑safe containers (with proper handling)

- Mechanical components

✅ Durable and easy to print

❌ Can be stringy

4. TPU (Thermoplastic Polyurethane)

Made from:

- Rubber‑like elastomeric polymers

Key properties:

- Flexible and elastic

- Shock‑absorbing

- Abrasion‑resistant

Best for:

- Phone cases

- Gaskets

- Wearable items

✅ Very flexible

❌ Difficult to print on some printers

5. Nylon (Polyamide)

Made from:

- Synthetic petroleum‑based polymers

Key properties:

- Extremely strong

- Wear‑resistant

- High heat tolerance

Best for:

- Gears

- Mechanical parts

- Industrial components

✅ Tough and durable

❌ Absorbs moisture easily

Specialty & Composite Filaments

Carbon Fiber Filament

- Base plastic (PLA, PETG, or Nylon) infused with carbon fibers

- Strong and lightweight

- Requires hardened nozzles

Wood Filament

- PLA mixed with wood fibers

- Produces a wood‑like finish

- Can be sanded and stained

Metal‑Filled Filament

- Plastic mixed with metal powders (bronze, copper, steel)

- Heavy and metallic appearance

- Can be polished after printing

Additives in Filament

Most filaments also include:

- Color pigments

- UV stabilizers

- Plasticizers

- Strength or flexibility enhancers

These additives improve print quality and durability.

Is 3D Printer Filament Safe?

- PLA: Generally safe and low‑odor

- ABS & Nylon: Emit fumes—use ventilation

- Food safety: Depends on material, printer cleanliness, and post‑processing

⚠️ Always print in a well‑ventilated area.

How Filament Is Manufactured

- Raw plastic pellets are melted

- Extruded into thin strands

- Diameter is precisely controlled

- Cooled and wound onto spools

- Quality‑checked for consistency

Choosing the Right Filament

| Use Case | Best Material |

|---|---|

| Beginner projects | PLA |

| Strong parts | PETG, ABS |

| Flexible items | TPU |

| High‑stress parts | Nylon |

| Visual appeal | Wood or silk PLA |

Final Thoughts

3D printer filament is made from a wide range of thermoplastic polymers, each designed for different purposes. Understanding what filament is made of helps you:

- Choose the right material

- Improve print quality

- Avoid common printing issues

Whether you’re printing a simple model or an industrial‑grade part, the right filament makes all the difference.

Key Takeaways

- 3D printer filament is primarily made of thermoplastics that melt when heated and harden when cooled to form your printed objects.

- PLA filament stands out as an eco-friendly option made from organic materials, while other filaments like ABS are petroleum-based.

- Your filament choice directly affects your print’s strength, flexibility, and temperature resistance, making material selection crucial for project success.

Overview of 3D Printer Filament

3D printer filament is the material fed into a 3D printer to create objects. This thermoplastic thread comes spooled and melts when heated, allowing it to be shaped into various forms as it cools and solidifies.

Materials Commonly Used for Filament

The most popular filament material is PLA (Polylactic Acid), which is made from organic materials rather than petroleum. This makes it more environmentally friendly than other options.

ABS (Acrylonitrile Butadiene Styrene) is another common material, known for its durability and higher temperature resistance. It’s the same plastic used in LEGO bricks.

Other common filament materials include:

- PETG: Combines strength and flexibility

- TPU: Flexible and rubber-like

- Nylon: High strength and durability

- PVA: Water-soluble, used for support structures

Most filaments start as plastic pellets that get melted and extruded into a continuous thin thread during manufacturing.

Properties of Filament Materials

Different filament materials offer varying properties that make them suitable for specific applications. Understanding these properties helps you choose the right filament for your project.

Strength: Nylon and ABS provide excellent structural strength, while PLA is more brittle.

Temperature Resistance: ABS withstands higher temperatures (up to 105°C) compared to PLA (around 60°C).

Flexibility: TPU offers rubber-like flexibility, while PETG provides moderate flexibility with good strength.

Printing Difficulty:

- Easy: PLA (low warping, minimal odor)

- Moderate: PETG, TPU

- Difficult: ABS (prone to warping, strong odor)

The filament-making process involves several steps from raw materials to final product. Diameter consistency is crucial, with most filaments available in either 1.75mm or 2.85mm sizes for different printer types.

Types of 3D Printer Filament

3D printer filaments come in various materials, each with unique properties that make them suitable for different applications. The right choice depends on your project’s specific requirements for strength, flexibility, temperature resistance, and appearance.

Polylactic Acid (PLA)

PLA is one of the most popular filaments for 3D printing beginners and professionals alike. Made from organic materials like corn starch or sugar cane, PLA is biodegradable and produces a pleasant sweet smell when printing.

This filament prints at lower temperatures (180-220°C) and doesn’t require a heated bed, making it easier to work with on basic printers. PLA produces parts with good detail and minimal warping.

Key properties of PLA include:

- Strength: Medium strength but somewhat brittle

- Flexibility: Low (rigid material)

- Durability: Lower than ABS, not ideal for outdoor use

- Ease of Use: Very high (beginner-friendly)

PLA is perfect for decorative items, prototypes, and low-stress indoor applications. It comes in countless colors and specialty variations like wood-filled, metal-filled, and carbon fiber PLA for enhanced properties.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic known for its durability and heat resistance. This filament creates tough parts that can withstand higher temperatures and mechanical stress than PLA.

Printing with ABS requires higher temperatures (220-250°C) and a heated bed (95-110°C) to prevent warping. Good ventilation is necessary as ABS emits fumes during printing.

ABS advantages include:

- Impact resistance: Excellent for functional parts

- Heat tolerance: Withstands temperatures up to 100°C

- Post-processing: Can be sanded, drilled, and painted easily

- Chemical resistance: Holds up well against many chemicals

You’ll find ABS in automotive parts, household items, and electronics enclosures. The material can be smoothed using acetone vapor for a glossy finish. Many Lego bricks are made from ABS, demonstrating its durability and longevity.

Polyethylene Terephthalate (PET)

PET and its glycol-modified version PETG combine many of the best qualities of PLA and ABS. This filament offers excellent strength, durability, and temperature resistance without the printing difficulties of ABS.

PETG prints at moderate temperatures (220-250°C) with minimal warping and odor. It produces parts with good layer adhesion and impact resistance.

Notable characteristics include:

- Clarity: Can print clear or translucent parts

- Food safety: Many versions are FDA approved for food contact

- Water resistance: Excellent for containers and outdoor items

- Flexibility: Slightly flexible while maintaining strength

You’ll appreciate PETG for functional parts that need durability, weather resistance, and good visual appearance. Water bottles, mechanical parts, and protective cases are common applications for this versatile material.

Nylon

Nylon filaments create exceptionally strong, durable, and slightly flexible parts. This engineering-grade material offers excellent wear resistance and low friction properties.

Printing nylon requires high temperatures (240-260°C) and careful handling as it absorbs moisture from the air. A heated bed (80-100°C) and enclosed printer are recommended.

Key nylon properties include:

- Tensile strength: One of the strongest printable plastics

- Abrasion resistance: Excellent for moving parts

- Impact resistance: Superior to most other filaments

- Layer adhesion: Very good, creating solid parts

Nylon is ideal for functional prototypes, tools, gears, hinges, and other mechanical components. You should store nylon filament in airtight containers with desiccant to prevent moisture absorption, which can cause poor print quality.

High Impact Polystyrene (HIPS)

HIPS is primarily used as a support material for ABS prints but can also serve as a primary printing material. It has similar printing characteristics to ABS but can be dissolved in limonene (citrus-based solvent).

When printing HIPS, you’ll need similar settings to ABS: high temperatures (230-245°C) and a heated bed (95-115°C).

HIPS features include:

- Dissolvability: Dissolves in limonene for complex support structures

- Lightweight: Lower density than many other filaments

- Impact resistance: As the name suggests, it absorbs impacts well

- Machinability: Easy to sand, drill, and paint

You can use HIPS for creating complex ABS prints with dissolvable supports, lightweight prototypes, and architectural models. When used as a support material, HIPS allows for printing geometries that would be impossible with breakaway supports.

Technical Materials

Beyond standard filaments, specialized technical materials offer enhanced properties for specific applications.

Polycarbonate (PC) offers incredible strength and heat resistance (up to 110°C). It requires very high printing temperatures (260-310°C) and an enclosed chamber.

TPE/TPU (flexible filaments) provide rubber-like properties with varying hardness levels. These materials create parts that can bend, stretch, and compress.

Other technical filaments include:

- Carbon fiber composites: Rigid, lightweight, and dimensionally stable

- Metal-filled filaments: Contain metal particles for weight and appearance

- Wood-filled filaments: Contain wood particles for appearance and texture

- Conductive filaments: Allow printing of simple circuits and sensors

These materials often require specialized nozzles, higher temperatures, and careful print settings. You should research specific handling requirements before attempting to print with these advanced filaments.

Specific Filament Properties

3D printer filament properties determine how your final prints will perform under various conditions. Different filaments offer unique combinations of strength, flexibility, and resistance that make them suitable for specific applications.

Tensile Strength and Ductility

Tensile strength measures how much stretching force a filament can withstand before breaking. PLA typically offers moderate tensile strength of 50-70 MPa, making it good for decorative items but less ideal for functional parts.

ABS provides better ductility, allowing it to bend without breaking as easily as PLA. This makes ABS more suitable for parts that need to withstand stress.

PETG combines good tensile properties (45-60 MPa) with flexibility, offering a middle ground that works well for many projects.

For high-strength applications, consider nylon filaments, which can reach tensile strengths above 80 MPa. Carbon fiber-filled filaments provide even higher strength values, with some enhanced filaments exceeding 100 MPa.

Impact Resistance and Strength

Impact resistance determines how well your printed parts can absorb sudden forces without breaking. ABS excels in this area, making it ideal for protective cases, automotive parts, and toys.

Polycarbonate (PC) offers exceptional impact strength and is used in applications where durability is critical. Many police shields and protective equipment use PC for this reason.

TPU and other flexible filaments provide outstanding impact absorption due to their elastic nature. These materials can bend and flex to dissipate energy rather than cracking.

PLA has poor impact resistance and will typically shatter when subjected to sudden forces. If you need both strength and impact resistance, consider filament blends like PLA+, which improve upon PLA’s mechanical properties.

Temperature and Chemical Resistance

Heat resistance varies dramatically between filaments. PLA begins to soften at relatively low temperatures (55-60°C), making it unsuitable for items exposed to heat.

ABS can withstand temperatures up to about 105°C, while PETG remains stable to approximately 75°C. For high-temperature applications, consider polycarbonate (140°C) or PEEK (250°C+).

Chemical resistance is equally important for certain applications. Nylon resists many chemicals but absorbs water. PETG offers good resistance to acids and alkalis, making it suitable for containers.

TPU shows excellent resistance to oils and many solvents. For maximum chemical resistance, specialty filaments like PP (polypropylene) or PVDF provide exceptional protection against harsh substances.

Elongation and Mechanical Properties

Elongation measures how much a material can stretch before breaking. TPU offers incredible elongation at 580-600%, allowing it to stretch to several times its original length and return to shape.

Nylon provides good elongation (50-100%) while maintaining strength, making it perfect for hinges and mechanical parts that need flexibility.

Standard PLA is quite brittle with only 3-6% elongation. If you need more flexibility, modified PLA blends can reach 7-12%.

Layer adhesion also affects mechanical performance. Thermoplastic filaments with better layer bonding create stronger parts. Print orientation significantly impacts your part’s final strength, as parts are generally weaker along the Z-axis due to layer lines.

Filament Enhancements and Additives

Filament manufacturers have developed various additives that significantly improve the performance and functionality of 3D printing materials. These enhancements expand what you can create with your printer while solving common printing challenges.

Carbon Fiber Infused Filament

Carbon fiber filaments combine standard thermoplastics like PLA or ABS with carbon fiber particles to enhance mechanical properties. These specialized filaments typically contain 15-30% carbon fiber content, providing remarkable stiffness and dimensional stability to your prints.

The addition of carbon fiber creates parts that are lighter yet stronger than standard filament versions. You’ll notice these materials have less flex and warping, making them ideal for functional prototypes and end-use parts that need structural integrity.

However, carbon fiber infused filaments are more abrasive than standard materials. You’ll need a hardened steel nozzle to prevent excessive wear on your printer. These filaments also tend to be more brittle during printing, requiring careful handling.

Projects best suited for carbon fiber filaments include drone parts, robotics components, and automotive applications where weight reduction matters but strength can’t be compromised.

Tough PLA and Enhanced Polyesters

Tough PLA represents a significant upgrade from standard PLA, offering improved impact resistance without sacrificing ease of printing. These enhanced formulations add specialized modifiers to the base polymer that increase flexibility while maintaining good print quality.

When printing with tough PLA, you’ll experience similar printing temperatures to regular PLA (around 210-230°C) but gain parts that can bend without breaking. This makes it perfect for functional prototypes that need to withstand repeated handling or stress testing.

Enhanced polyesters, like PETG with additives, provide excellent layer adhesion and chemical resistance. These materials often include impact modifiers or UV stabilizers that extend the useful life of your prints in demanding environments.

You’ll find these enhanced filaments particularly useful for outdoor fixtures, tool handles, or mechanical parts that need to absorb vibration rather than crack under pressure.

Soluble Support Filaments

HIPS (High Impact Polystyrene) and PVA (Polyvinyl Alcohol) are specialized soluble filaments designed to create removable support structures for complex prints. These materials dissolve in specific solvents, leaving your main print intact and support-free.

PVA dissolves in water, making it environmentally friendly and easy to work with. It pairs especially well with PLA for creating complex geometries with internal cavities that would be impossible to print otherwise.

HIPS dissolves in limonene (a citrus-based solvent) and works best when paired with ABS. When using dual extrusion printers, you can create incredibly detailed models with perfect overhangs by printing supports that completely disappear after processing.

The main advantage of soluble supports is the flawless surface finish they enable. You won’t need to sand or cut away support marks, resulting in professional-quality prints with minimal post-processing.

Filament Selection for Quality Printing

Choosing the right filament is crucial for achieving successful 3D prints that meet your specific needs. The material you select affects everything from durability to appearance.

Determining the Right Filament for the Job

When selecting filament, consider what you’re printing and how the final object will be used. PLA filament is great for beginners due to its ease of use and biodegradable properties.

For functional parts that need to withstand stress, consider these options:

- PETG: Higher strength and temperature resistance than PLA

- ABS: Durable with good impact resistance

- Nylon: Extremely strong and flexible

Specialty filaments serve unique purposes:

- Flexible filaments: For parts that need to bend

- Metal-filled: For realistic metal appearance and weight

- Wood-filled: For a natural wood-like finish

Your printer’s capabilities also matter. Check if your machine can reach the temperatures needed for your chosen material. Some filaments like ABS require enclosed printing spaces.

Impact on Print Quality

The filament you choose directly affects your print quality. Fresh, properly stored filament produces better results than old or moisture-exposed materials.

Filament diameter consistency is critical. High-quality brands maintain tight tolerances (±0.05mm), resulting in more predictable extrusion and better prints.

Temperature settings must match your filament type. Each material has an optimal printing temperature range:

| Filament Type | Ideal Bed Temp (°C) | Ideal Nozzle Temp (°C) |

|---|---|---|

| PLA | 50-60 | 190-220 |

| PETG | 70-90 | 230-250 |

| ABS | 95-110 | 230-250 |

Print speed should be adjusted based on your material. PLA can print faster, while specialty filaments often require slower speeds for best results.

Consider bed adhesion requirements too. Some materials need special surfaces or adhesives to prevent warping during printing.

Frequently Asked Questions

Understanding different filament materials helps you select the right one for your projects. Each material has unique properties that affect how your 3D prints turn out.

What are the common materials used for 3D printer filaments?

The most common 3D printer filaments are PLA and ABS. PLA (polylactic acid) is made from organic materials, unlike most filaments that contain petroleum.

ABS (acrylonitrile butadiene styrene) is another popular option. Other widely used materials include PETG, TPU, Nylon, and various specialty filaments designed for specific applications.

Many materials can be used to create 3D printing filaments, each offering different properties for various printing needs.

How do the properties of PLA filament compare to those of other 3D printing materials?

PLA is easier to print with than most other filaments. It melts at a lower temperature (around 180-220°C) and doesn’t require a heated bed.

PLA is more rigid but more brittle than ABS or PETG. It’s also biodegradable, making it more environmentally friendly than petroleum-based alternatives.

The downside is that PLA has lower heat resistance. Your PLA prints might deform if left in a hot car, while ABS or PETG prints would maintain their shape.

Can you use fabric as a material for 3D printer filament?

Traditional 3D printer filaments are continuous plastic threads and not made from fabric. Currently, fabric cannot be directly used as 3D printer filament in conventional FDM printers.

Some researchers are exploring ways to incorporate textile fibers into filaments. Composite filaments that blend plastic with small amounts of fabric fibers do exist, but pure fabric filament isn’t commercially viable.

You can, however, 3D print onto fabric using traditional filaments to create interesting combined materials.

What environmental impacts are associated with the use of 3D printer filaments?

Most 3D printer filaments are plastic-based and carry similar environmental concerns as other plastics. Petroleum-based filaments like ABS contribute to fossil fuel consumption and release potentially harmful fumes during printing.

Failed prints and support materials often end up as waste. Many filaments aren’t easily recyclable in standard municipal recycling programs.

Energy consumption during printing also creates an environmental footprint, especially for prints requiring high temperatures or long print times.

Are there biodegradable options for 3D printer filaments?

Yes, PLA is the most common biodegradable 3D printing filament. It’s made from organic materials like corn starch or sugarcane.

Other biodegradable options include PHA (polyhydroxyalkanoate) and various PLA blends. These materials will break down under specific composting conditions, though they may take months or years depending on the environment.

Remember that “biodegradable” doesn’t mean the filament will break down in your home compost bin. Most require industrial composting facilities with controlled temperature and humidity.

What distinguishes PETG filament from other types of 3D printing materials?

PETG (Polyethylene Terephthalate Glycol) offers an excellent middle ground between PLA and ABS. It’s more durable and heat-resistant than PLA but easier to print with than ABS.

PETG has strong layer adhesion, making it ideal for water-tight containers and functional parts. It also has good chemical resistance and remains more flexible than PLA.

Unlike ABS, PETG doesn’t require an enclosure and produces minimal odor when printing. It’s food-safe (though print surfaces can harbor bacteria) and recyclable, making it popular for many practical applications.