A hot compressor in your freezer is a common concern for many homeowners. The compressor, which circulates refrigerant throughout the cooling system, naturally generates heat during operation. While a warm compressor is normal, excessive heat can indicate underlying issues that need attention.

To prevent compressor overheating, proper maintenance and a clear understanding of the cooling process are essential. Regularly cleaning the condenser coils, ensuring adequate airflow, and maintaining appropriate internal temperatures are crucial steps. These actions help promote efficient operation and can extend the lifespan of your freezer.

It’s also important to recognize when professional help is needed. If the compressor feels unusually hot or if you notice a decline in the freezer’s performance, consulting a qualified technician can help prevent further damage. Taking prompt action can save you money on repairs and prevent food spoilage.

While it’s normal for a freezer compressor to feel warm or even hot to the touch, if it’s so hot that you can’t keep your hand on it, there may be a problem. Here are some reasons why your freezer compressor might be overheating:

1. Poor Air Circulation

- Blocked Vents: Make sure nothing is blocking the vents inside or outside your freezer. Good airflow is essential for keeping the compressor cool.

- Dirty Condenser Coils: Dust and debris can build up on the condenser coils, making it harder for the compressor to release heat. Clean the coils regularly with a vacuum or brush.

2. Overworking

- Door Seal Issues: A damaged door seal can let warm air into the freezer, forcing the compressor to work harder to maintain the temperature. Check the seal and replace it if necessary.

- Thermostat Problems: A faulty thermostat can cause the compressor to run continuously, leading to overheating. If you suspect a thermostat issue, it’s best to call a professional.

- Overfilled Freezer: An overstuffed freezer restricts airflow and makes the compressor work harder. Keep your freezer organized and avoid overcrowding.

3. Refrigerant Leak

- Low Refrigerant Levels: If your freezer is leaking refrigerant, the compressor has to work harder to cool the freezer, which can cause it to overheat. Refrigerant leaks require professional repair.

4. Electrical Issues

- Voltage Problems: An insufficient or excessive voltage supply can cause the compressor to overheat. If you suspect an electrical issue, consult an electrician.

- Faulty Wiring: Damaged or loose wiring can also lead to overheating. Check for any visible damage and call a professional if you find any.

5. Compressor Issues

- Failing Compressor: If the compressor itself is failing, it may overheat. This usually requires a professional to diagnose and replace the compressor.

What to Do

- Check for Obvious Issues: Start by checking for easy-to-fix problems like blocked vents, dirty coils, and door seal issues.

- Clean the Coils: Regularly cleaning the condenser coils can prevent overheating and improve efficiency.

- Call a Professional: If you suspect a more serious issue like a refrigerant leak, thermostat problem, or failing compressor, it’s best to call a qualified appliance repair technician.

Preventing Overheating

- Regular Maintenance: Clean the condenser coils every few months and check the door seal regularly.

- Proper Ventilation: Ensure adequate space around the freezer for proper ventilation.

- Don’t Overfill: Avoid overfilling the freezer to allow for proper airflow.

If you’re unsure about any of these issues or how to address them, it’s always best to consult a professional appliance repair technician. They can diagnose the problem accurately and provide the necessary repairs.

Key Takeaways

- A warm compressor is normal, but excessive heat may indicate problems

- Regular maintenance helps prevent compressor overheating

- Professional help is vital if the compressor feels unusually hot

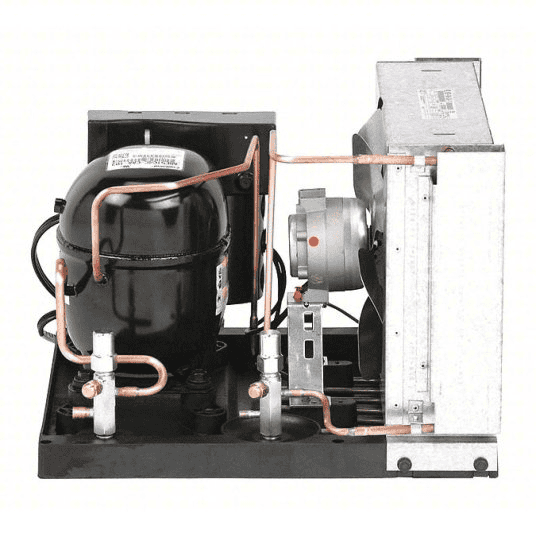

Components of a Freezer Compressor System

A freezer compressor system consists of several key parts working together to maintain cold temperatures. These components play crucial roles in the refrigeration cycle, ensuring efficient cooling and food preservation.

Role of the Compressor in the Cooling Cycle

The compressor is the heart of the freezer system. It pumps refrigerant through the cooling circuit. The compressor pressurizes the refrigerant gas, raising its temperature and pressure. This process kickstarts the cooling cycle.

As the compressor runs, it generates heat. This heat is normal and indicates proper functioning. However, excessive heat may signal problems. Regular maintenance helps prevent overheating issues.

The compressor typically cycles on and off to maintain the set temperature. Its operation is controlled by a thermostat that monitors the freezer’s internal temperature.

Function of the Condenser

The condenser releases heat from the refrigerant to the surrounding air. It’s usually located at the back of the freezer. Hot, high-pressure gas from the compressor enters the condenser coils.

As the gas moves through the coils, it cools and condenses into a liquid. This process is crucial for heat removal. The condenser’s efficiency affects the freezer’s overall performance.

Dirty condenser coils can reduce cooling efficiency. Regular cleaning of the coils helps maintain optimal heat transfer. Some freezers have built-in fans to assist air circulation around the condenser.

Importance of the Evaporator

The evaporator absorbs heat from inside the freezer. It’s typically located inside the freezer compartment. The liquid refrigerant enters the evaporator at low pressure.

As the refrigerant evaporates, it absorbs heat from the freezer’s contents. This process cools the interior space. The evaporator coils may develop frost, which is removed during defrost cycles.

Proper air circulation around the evaporator is essential. Overpacking the freezer can block airflow and reduce cooling efficiency. Some freezers use fans to distribute cold air evenly.

Condenser Fan and Air Circulation

The condenser fan plays a vital role in heat dissipation. It blows air across the condenser coils to help cool the refrigerant. This fan typically runs whenever the compressor is operating.

A malfunctioning condenser fan can lead to overheating. Regular cleaning of the fan blades prevents dust buildup. Some freezers also have an evaporator fan inside the unit.

The evaporator fan circulates cold air throughout the freezer. It helps maintain consistent temperatures. Proper air circulation prevents warm spots and ensures even cooling of stored items.

Common Causes of Freezer Compressor Overheating

Freezer compressor overheating can stem from several factors. These issues can lead to decreased efficiency, higher energy costs, and potential appliance damage.

Impact of Dirty Condenser Coils

Dirty condenser coils significantly affect freezer compressor performance. These coils release heat from the refrigeration system to the surrounding air. When dust and debris accumulate on the coils, they act as insulation, trapping heat.

This buildup forces the compressor to work harder and longer to maintain the desired temperature. The increased workload leads to overheating and excessive energy consumption. Regular cleaning of condenser coils is crucial for optimal freezer operation.

Homeowners can clean the coils using a vacuum cleaner or soft brush. For best results, this maintenance task should be performed every 6-12 months.

Significance of Refrigerant Levels

Proper refrigerant levels are essential for freezer compressor function. Low refrigerant, often due to leaks, causes the compressor to run continuously. This prolonged operation results in overheating and potential failure.

Signs of low refrigerant include:

- Inconsistent freezer temperatures

- Unusual noises from the compressor

- Frost buildup on evaporator coils

A certified technician should check and recharge refrigerant levels. They can also identify and repair any leaks in the system.

Consequences of Poor Ventilation

Adequate ventilation is crucial for freezer compressor cooling. Restricted airflow around the appliance traps heat, leading to compressor overheating. This issue is common in built-in freezers or those placed in tight spaces.

To ensure proper ventilation:

- Leave 1-2 inches of space on all sides of the freezer

- Keep the area around the freezer clear of obstructions

- Avoid placing the freezer near heat sources like ovens or direct sunlight

Poor ventilation not only causes compressor overheating but also reduces overall freezer efficiency. It can lead to food spoilage and increased energy bills. Proper placement and regular cleaning of the surrounding area can prevent these issues.

Maintenance and Troubleshooting

Regular maintenance and prompt troubleshooting are essential for keeping freezer compressors running efficiently and preventing overheating issues. Proper care can extend the lifespan of the appliance and reduce energy costs.

Regular Cleaning and Inspection

Routine cleaning of the freezer’s condenser coils is crucial. These coils release heat from the refrigerant, and when dirty, they force the compressor to work harder. Users should unplug the freezer and locate the coils, typically at the back or bottom of the unit. A vacuum cleaner with a brush attachment can remove dust and debris.

Inspecting the door seal is equally important. A faulty seal allows warm air to enter, causing the compressor to run more frequently. To check the seal, close the door on a dollar bill. If it slides out easily, the seal may need replacement.

The defrost timer should be examined regularly. A malfunctioning timer can lead to excessive frost buildup, which impedes airflow and strains the compressor. If frost accumulates quickly, the timer may need adjustment or replacement.

Detecting and Fixing Refrigerant Leaks

Refrigerant leaks can cause compressor overheating and reduced cooling efficiency. Signs of a leak include:

- Warm freezer temperatures

- Hissing sounds near the compressor

- Oil residue around connections

Leak detection kits are available for home use, but professional assistance is recommended for accurate diagnosis and repair. Technicians use specialized equipment to locate and fix leaks safely.

Recharging the refrigerant should only be done by certified professionals. Improper handling can be dangerous and may violate environmental regulations.

Ensuring Adequate Airflow

Proper ventilation is critical for compressor health. The freezer should have at least 3 inches of clearance on all sides to allow air circulation. Avoid placing items on top of the freezer that could block vents.

Inside the freezer, organize contents to promote air circulation. Overstocking can restrict airflow, forcing the compressor to work harder. Use baskets or organizers to keep items tidy and allow cold air to flow freely.

Check the internal fan for proper operation. A malfunctioning fan can lead to uneven cooling and compressor strain. If the fan is noisy or not spinning, it may need replacement.

Professional Intervention and Repair

Professional assistance is crucial for addressing serious compressor issues and ensuring energy efficiency. Experts can identify complex problems and provide effective solutions to keep freezers running optimally.

Identifying Serious Compressor Issues

Homeowners should watch for signs of severe compressor problems. Unusual noises like grinding or rattling often indicate internal damage. Frequent cycling on and off may point to electrical issues. A compressor that feels excessively hot or fails to cool properly requires immediate attention.

Professionals use specialized tools to diagnose compressor faults. They check refrigerant levels, test electrical components, and measure temperature differentials. These diagnostics help pinpoint exact problems, whether it’s a faulty start relay, worn bearings, or a refrigerant leak.

Experts can also detect early warning signs of impending failure. This allows for preventive repairs, potentially saving owners from costly compressor replacements.

Energy Efficiency Considerations

A malfunctioning compressor can significantly increase energy consumption. Professionals assess the overall efficiency of the freezer system. They examine factors like insulation quality, door seals, and coil cleanliness.

Technicians may recommend upgrades to improve energy performance:

- Installing a more efficient compressor

- Replacing outdated thermostats

- Adding insulation to reduce heat gain

These improvements can lead to lower electricity bills and extended freezer lifespan. Experts can provide cost-benefit analyses of potential upgrades, helping owners make informed decisions.

Regular maintenance by professionals also contributes to energy efficiency. Clean coils and proper refrigerant levels ensure the compressor runs optimally, reducing unnecessary strain and energy waste.

When to Seek Professional Assistance

Certain situations demand immediate professional help:

- Compressor won’t start or run continuously

- Freezer temperature rises above safe levels

- Unusual odors or smoke coming from the unit

- Visible damage to compressor or electrical components

For chest freezers, owners should call experts if the compressor runs but fails to cool. This could indicate a sealed system leak requiring specialized repair.

DIY attempts at major compressor repairs can be dangerous and often lead to further damage. Professionals have the training and equipment to safely handle refrigerants and electrical systems.

Regular professional maintenance can prevent many serious issues. Scheduling annual check-ups helps catch problems early, extending the life of the freezer and its compressor.

Frequently Asked Questions

Freezer compressor issues can lead to various problems. Understanding common concerns helps troubleshoot and maintain optimal freezer performance.

Why is my freezer’s compressor overheating?

A freezer compressor may overheat due to dirty condenser coils, poor ventilation, or a faulty fan motor. Regular cleaning of coils and ensuring proper airflow around the freezer can prevent overheating. If the problem persists, a professional inspection may be necessary.

What should I do if my fridge compressor is hot but not running?

A hot compressor that’s not running might indicate a failed start relay or capacitor. Unplug the refrigerator and allow the compressor to cool. If the issue continues, contact a technician to check and replace faulty components.

What are the signs of a failing freezer compressor?

Signs of a failing compressor include unusual noises, frequent cycling, and inadequate cooling. Food spoilage, frost buildup, and increased energy bills can also indicate compressor problems. Regular maintenance can help detect these issues early.

How can I fix an overheating compressor in my refrigerator?

To fix an overheating compressor, first ensure proper ventilation around the fridge. Clean the condenser coils and check for proper fan operation. If these steps don’t resolve the issue, a professional assessment may be required to diagnose and repair more complex problems.

Is it typical for a refrigerator compressor to feel hot to the touch?

It is normal for a refrigerator compressor to feel warm or hot to the touch during operation. The compressor generates heat as it pressurizes refrigerant. However, if it feels excessively hot or causes discomfort when touched, further investigation is warranted.

Why does my freezer compressor emit a buzzing sound and heat up?

A buzzing sound from a freezer compressor often indicates an electrical issue or a problem with the start relay. The combination of noise and heat may suggest the compressor is struggling to start or run properly. This situation requires prompt attention from a qualified technician to prevent further damage.